Deck Builders Utah County

Utah’s Premier Deck Builders & Framing

It’s in the Details: Deck Material and Joint Matters

Today, deck builders have a variety of materials with which to work. However, wood remains a preferred medium for many homeowners. That’s why the seasoned professionals at Hawkeye Framing make it a point to source the best lumber and use the most rigorous safety measures in every project. Framing contractors in Utah who offer clients their services for exterior construction know that there are a number of factors to consider when sourcing materials. Below, we’ll examine what products are best to use in a deck construction project.

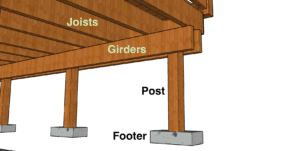

Footings and Main Supports

While it’s perfectly acceptable to use pressure-treated wood as a primary support pillar, there are a few issues associated with this tactic that clients may wish to avoid. Pressure-treated wood stands up to the elements far better than lumber that is simply coated with a protective substance, such as a deck stain. The pillars are then seated in a protective footing of concrete, which insulates the wood against direct contact with earth, moisture, and other environmental factors.

There are alternatives to using lumber for this particular aspect of deck framing, which even a wood deck builder may consider appropriate. Composite timbers, which are made from recycled plastics, and reinforced concrete timbers may be used, although these types of materials are usually reserved for commercial construction. A seasoned deck building contractor may determine that the context for the new residential deck merits these more advanced measures.

Hardware

Any deck builder knows that lumber quality matters when considering deck framing projects. However, deck contractors also consider hardware quality and the needs of a specific project. Appropriate fasteners, t-joints, and bolts can make the difference between an unsafe deck framing endeavor and a proper, safe frame that can be finished with confidence.

The best framing contractors in Utah avail themselves freely of the latest and most innovative structural hardware. This ranges from connectors to adjust the position of a pillar in a footing to reinforced t-joints that provide extra stability between posts and deck struts. They may even use post struts to adjust the height of a support in the event of settling or uneven context since residential properties often present challenges of terrain.

Another innovative product used by an experienced wood deck builder is the concealed flange hangar. This is a structural attachment that joins deck struts to the ledger and upright posts. While in the past deck contractors might merely hammer the flange flush around the corner of the timber, this actually presents problems of flaking galvanization on the flange and voids the warranty on the joist.

For clients who want to design an asymmetrical or angled deck, skewed hangers allow the deck building contractor to adjust the angle of attachment for struts in relation to posts and the ledger.

A deck builder must consider the needs of the environment in which the structure is situated, the design needs of the client, and the current developments in structural support and design safety. If you’re seeking a reliable, knowledgeable wood deck builder, consider consulting Hawkeye Framing. We offer each client the benefit of our decades of experience and bring only the most current skill set to each framing project.